Introduction: The Need for Asset Care in Uganda

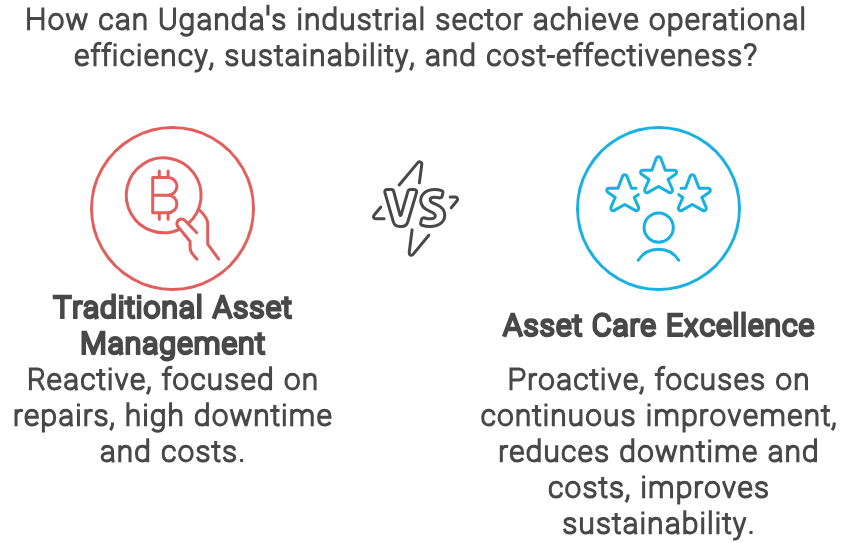

As Uganda’s industrial sector continues to grow, the demand for operational efficiency, sustainability, and cost-effectiveness has never been higher. The success of manufacturing plants, industrial facilities, and large-scale packaging companies hinges on their ability to maintain and improve the reliability and performance of their assets. Yet, the challenge of achieving these goals can be daunting without a comprehensive approach to asset management. This is where the concept of Asset Care Excellence comes into play—a strategy designed to ensure that industrial assets are not only maintained but continuously improved to meet the evolving demands of the market.

Asset Care Excellence is more than just routine maintenance; it is about fostering a culture of continuous improvement, proactive management, and operational excellence. In Uganda, where the industrial landscape is still maturing, there is a unique opportunity to establish best practices that can set the standard for years to come. This article delves into the Ugandan Asset Care Excellence initiative, highlighting its importance, key services, and the impact it can have on the country’s industrial sector.

Understanding Asset Care Excellence

At its core, Asset Care Excellence is about maximizing the value of industrial assets over their entire lifecycle. This involves not only maintaining equipment to prevent failures but also optimizing its performance to improve productivity, reduce waste, and enhance sustainability. The concept encompasses several key components:

- Proactive Maintenance: Moving beyond reactive maintenance, Asset Care Excellence focuses on predicting and preventing equipment failures before they occur. This reduces downtime, extends the lifespan of assets, and improves overall operational efficiency.

- Cultural Change: Successful asset care requires a shift in mindset across the organization. It involves developing and coaching teams to embrace best practices, take ownership of their equipment, and strive for continuous improvement.

- Data-Driven Decision Making: By analyzing operational data, organizations can identify trends, validate issues, and prioritize improvements. This data-driven approach ensures that resources are allocated effectively, and that performance is continuously optimized.

- Sustainability: In today’s business environment, sustainability is a key consideration. Asset Care Excellence involves implementing practices that reduce energy consumption, minimize waste, and lower the environmental impact of industrial operations.

- Continuous Improvement: The journey to Asset Care Excellence is ongoing. Organizations must continually assess their performance, identify areas for improvement, and implement changes to achieve higher levels of efficiency and effectiveness.

Strategic Objectives of Asset Care Excellence

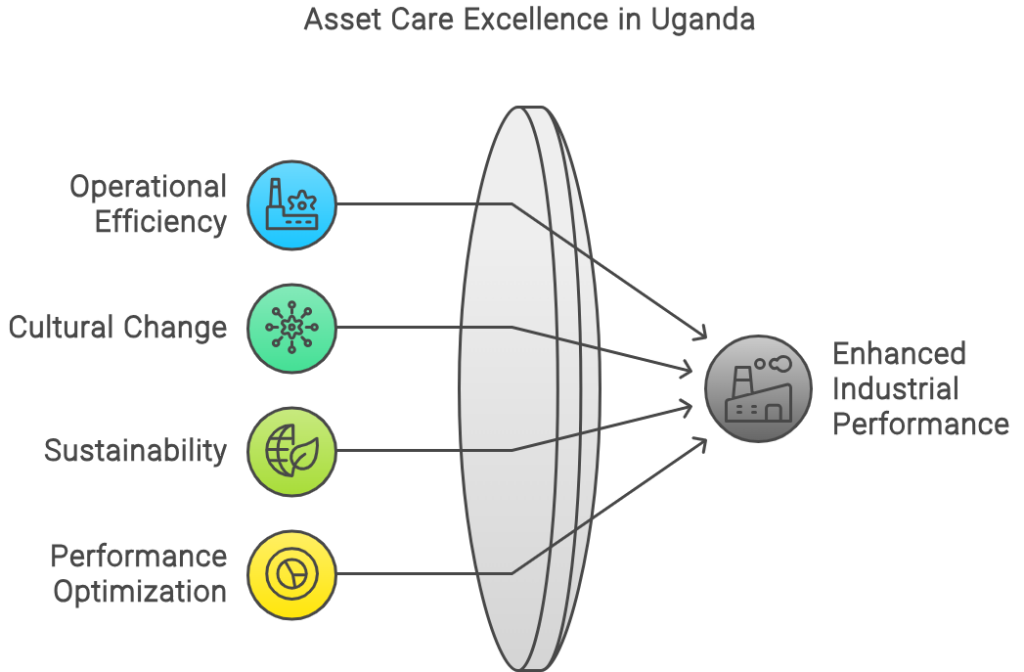

For the Ugandan industrial sector, the adoption of Asset Care Excellence can lead to significant benefits. The strategic objectives of this initiative are aligned with the broader goals of enhancing operational efficiency, fostering cultural change, and promoting sustainability.

Enhancing Operational Efficiency:

The primary goal of Asset Care Excellence is to improve the efficiency of industrial operations. This is achieved by minimizing downtime, reducing maintenance costs, and optimizing the performance of equipment. By adopting proactive maintenance strategies, organizations can ensure that their assets are always operating at peak efficiency, leading to higher production rates and lower operational costs.

Fostering Cultural Change:

One of the most important aspects of Asset Care Excellence is the focus on cultural change. This involves developing and coaching teams to adopt best practices, take ownership of their equipment, and strive for continuous improvement. By fostering a culture of excellence, organizations can create an environment where everyone is committed to achieving the highest standards of performance.

Promoting Sustainability:

Sustainability is a key consideration in today’s business environment. Asset Care Excellence involves implementing practices that reduce energy consumption, minimize waste, and lower the environmental impact of industrial operations. By aligning with global sustainability standards, Ugandan companies can enhance their reputation, reduce costs, and contribute to the long-term sustainability of the industry.

Performance Optimization:

Another critical objective is the continuous optimization of asset performance. This is achieved through the use of data-driven analysis to identify trends, validate issues, and prioritize improvements. By regularly monitoring and analyzing operational data, organizations can ensure that their assets are always performing at their best, leading to higher productivity and profitability.

Key Services Offered Under Asset Care Excellence

To achieve the objectives outlined above, the Ugandan Asset Care Excellence initiative offers a range of services designed to support organizations in their journey towards operational excellence.

Engineering Functional Expertise:

At the heart of Asset Care Excellence is the provision of expert engineering support. This involves working closely with operational teams to resolve complex equipment problems, optimize performance, and ensure that assets are maintained to the highest standards. By providing this expertise, the initiative helps organizations to improve their operational efficiency and reduce the risk of equipment failures.

Manufacturing Excellence Systems (MMS) Implementation:

The implementation of Manufacturing Excellence Systems (MMS) is a key component of the Asset Care Excellence initiative. MMS tools and techniques are designed to enhance manufacturing processes, improve efficiency, and ensure alignment with best practices. By supporting the implementation of MMS, the initiative helps organizations to achieve their operational goals and maintain a competitive edge in the market.

Performance Analysis & Improvement:

Data-driven decision-making is a cornerstone of Asset Care Excellence. The initiative provides expert analysis of operational data to identify trends, validate issues, and prioritize improvements. By leading ongoing improvement projects using the DMAIC (Define, Measure, Analyze, Improve, Control) methodology, the initiative ensures that organizations are continuously improving their asset performance and achieving higher levels of efficiency.

Training & Mentorship:

To ensure the effective deployment of asset care strategies, the initiative offers comprehensive training programs and mentorship to key personnel. This includes Packaging Team Leaders, Maintenance Support Leaders, and Reliability Leaders, who are responsible for the day-to-day management of assets. By providing ongoing training and mentorship, the initiative helps to develop a skilled and motivated workforce capable of maintaining high standards of asset care.

Continuous Monitoring & Review:

The success of Asset Care Excellence depends on continuous monitoring and review of performance. The initiative engages in regular operational reviews to provide expert analysis and identify opportunities for further improvement. By continuously monitoring performance, the initiative ensures that organizations are always striving for higher levels of efficiency and effectiveness.

Target Market: Who Can Benefit from Asset Care Excellence?

The primary target market for the Ugandan Asset Care Excellence initiative includes manufacturing plants, industrial facilities, and large-scale packaging companies. These organizations operate in highly competitive environments where operational efficiency and reliability are critical to success. By adopting Asset Care Excellence, they can achieve significant improvements in performance, reduce costs, and enhance their competitiveness in the market.

Additionally, the initiative is relevant to any organization that relies on industrial assets to support its operations. This includes sectors such as energy, mining, and transportation, where the reliability and performance of assets are crucial to operational success. By providing expert support and guidance, the initiative can help organizations in these sectors to achieve their operational goals and maintain a competitive edge.

Competitive Advantage: Why Choose Asset Care Excellence?

The Ugandan Asset Care Excellence initiative offers several key advantages that set it apart from other asset management solutions. These competitive advantages make it the preferred choice for organizations seeking to improve their operational performance and achieve long-term success.

Expertise:

The initiative is led by experienced professionals with deep knowledge of asset care and engineering best practices. This expertise ensures that organizations receive the highest level of support and guidance in their journey towards operational excellence.

Tailored Solutions:

One of the key strengths of the initiative is its ability to offer customized solutions that cater to the specific needs of each client. By taking a tailored approach, the initiative ensures that organizations receive solutions that are aligned with their operational goals and that deliver optimal outcomes.

Proactive Approach:

The initiative’s proactive approach to performance analysis and continuous improvement ensures that organizations stay ahead of potential issues. By identifying and addressing problems before they occur, the initiative helps organizations to minimize downtime, reduce costs, and improve overall efficiency.

Comprehensive Training:

The initiative places a strong emphasis on training and mentorship, ensuring that key personnel are equipped with the skills and knowledge they need to maintain high standards of asset care. This focus on training helps to develop a skilled and motivated workforce that is capable of driving continuous improvement and achieving long-term success.

Implementation Plan: How Asset Care Excellence is Delivered

The Ugandan Asset Care Excellence initiative is delivered through a structured implementation plan that ensures organizations receive the support they need at every stage of their journey. The implementation plan is divided into three key phases:

Phase 1: Assessment & Strategy Development

The first phase involves conducting site assessments to understand current asset care practices and identify areas for improvement. Based on this assessment, a tailored Asset Care Strategy is developed for each client, aligned with their operational goals and designed to deliver optimal outcomes.

Phase 2: MMS Implementation & Training

The second phase focuses on the implementation of Manufacturing Excellence Systems (MMS) and the delivery of training programs. MMS tools and techniques are implemented across the client’s operations to enhance efficiency and align with best practices. At the same time, comprehensive training programs are delivered to key personnel to ensure the effective deployment of asset care strategies.

Phase 3: Continuous Improvement & Monitoring

The final phase involves continuous monitoring and analysis of performance data to identify improvement opportunities. Ongoing improvement projects are led using the DMAIC methodology, ensuring that organizations are continuously improving their asset performance and achieving higher levels of efficiency.

Expected Outcomes: The Benefits of Asset Care Excellence

The adoption of Asset Care Excellence is expected to deliver a range of benefits for organizations in Uganda’s industrial sector. These benefits include:

Increased Equipment Reliability:

By implementing proactive maintenance strategies, organizations can reduce downtime, extend the lifespan of their assets, and improve overall equipment reliability. This leads to higher production rates, lower maintenance costs, and greater operational efficiency.

Enhanced Operational Efficiency:

The adoption of Manufacturing Excellence Systems (MMS) and the continuous optimization of asset performance lead to significant improvements in operational efficiency. Organizations can achieve higher production rates, reduce waste, and lower operational costs, resulting in increased profitability.

Sustainable Practices:

Asset Care Excellence promotes the adoption of sustainable practices that reduce energy consumption, minimize waste, and lower the environmental impact of industrial operations. By aligning with global sustainability standards, organizations can enhance their reputation, reduce costs, and contribute to the long-term sustainability of the industry.

Skilled Workforce:

The comprehensive training and mentorship provided by the initiative ensure that organizations develop a skilled and motivated workforce capable of maintaining high standards of asset care. This focus on workforce development helps to create a culture of excellence that drives continuous improvement and long-term success.

Conclusion: The Future of Asset Care in Uganda

The Ugandan Asset Care Excellence initiative represents a significant opportunity to enhance the performance and sustainability of industrial operations in the country. By providing expert engineering support, fostering cultural change, and driving continuous improvement, the initiative is poised to become the leading provider of asset care solutions in Uganda.

As the industrial sector continues to evolve, the importance of Asset Care Excellence will only grow. Organizations that adopt this approach will be well-positioned to achieve their operational goals, maintain a competitive edge, and contribute to the long-term success of Uganda’s industrial economy. For organizations seeking to improve their operational performance and achieve sustainable growth, the Ugandan Asset Care Excellence initiative offers a clear path to success.