What’s the path to growth for low-developing countries or for organizations that do not have an excessive level of resources? Disruptive Innovation is the path. One of the ways to innovate is through modularization. Thinking in terms of modules. This is happening in different industries.

Education

One of the challenges in education is that it takes time. For example, if a young professional wanted to upgrade their skills, they would have to take a considerable amount off work. Most Universities offer full-time courses. Thus, time spent in school is also foregone in earnings. Not many workplaces will give people the privilege to take a sabbatical for an education upgrade. The other alternative is the after-work education, where one signs up for evening and weekend classes. The pitfall in this is that by the time one leaves work, they are already exhausted for sensible education to happen.

That’s when the modular option comes in. A number of universities and other institutions have innovated around with the modular approach. Instead of requiring someone to attend University full-time, the course can be broken down into modules. A module could last a week or two with perhaps two or three units. Then, a potential student only needs to take off a week or two to attend a module, then they return to work. A year could have just three to four modules. The modules will compress the essentials and will be action-packed for that duration.

Energy

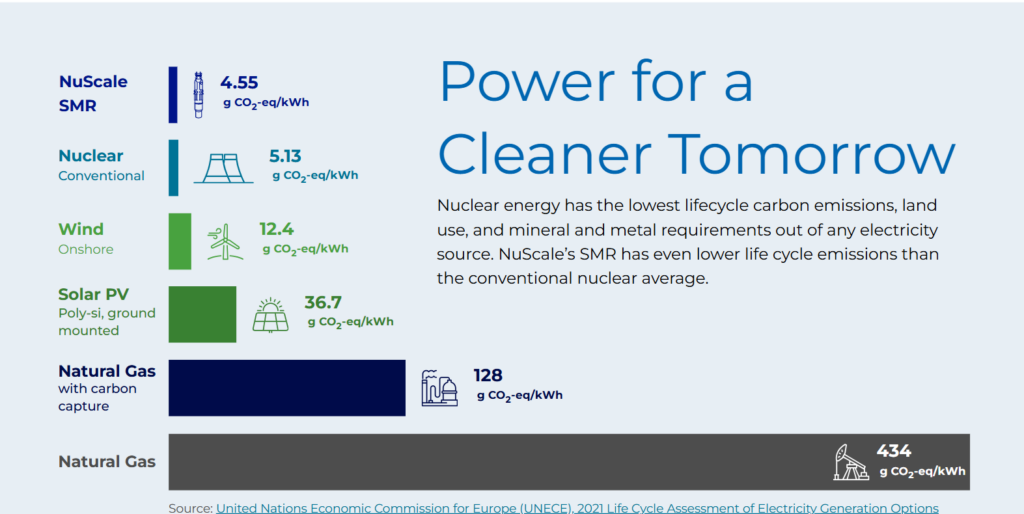

In Energy, countries such as India are crashing the cost of nuclear plants by producing modular nuclear reactors. This makes nuclear energy a possibility for countries such as Uganda, and Rwanda that may not afford the traditional power plants. These Indian reactors are able to produce power of up to 220 megawatts. Leading in these modular nuclear reactors are companies such as Nuscale, Constellation Energy and Oklo.

In built-environment cooling solutions, the modular approach is crashing the cost of Air-conditioning. With a floor-standing Air-conditioning system, one needs to not go with the full AC solution, that will probably be over-sized for most of the time, with a high operating cost.

Insight

At Ortega Group, we see the age of modularization taking over in many places. In manufacturing plants, this is also transforming how plants are being designed and installed. In housing, it’s easier to scale up with modular houses. And this is not a new technology, government classrooms in Uganda used to be constructed with the modular approach. Places such as Bugolobi Flats are a testament of this modular approach. Think in terms of modules as an Innovator. If you are designing and installing a carbondioxide plant, then break it into modules. All you will have to do is the tie-ins from one module to the next. It also becomes easier to upgrade such a plant. As a module can be upgraded without having to affect the operations of the entire plant.